If any of the following apply to you regarding mold development, we are the right partner for you

- You have a component to be potted that does not have its own housing?

- The component is to be installed in another, expensive housing later?

- You want daily production tracking, both manual and digital?

The dipotec team can find a solution here too. Through our longstanding know-how and our reliable partners, we can support you in your project.

The quick and reliable way to achieve ideal potting for your component

A component is to be potted but its geometry and properties do not allow for its own potting mold because an enveloping coating material has to be applied. This additional material requires a two-step process.

dipotec can advise you on the potting mold geometry and, together with your partners, produce a special potting mold in which you insert and pot the component.

This mold is made of metal and can be mechanically demolded to remove the component after the potting and curing process. During the curing process, the material does not bond with the potting mold thanks to the specially selected coating. The potted component easily detaches from the mold and can be easily removed.

This process ensures that dipotec can replicate any potting mold – whether simple or highly complex.

This is how your dipotec potting mold is developed

Idea

Check the component for its properties

Requirements

Definition of the final properties of the component after potting

Concept

Conception of a potting mold and definition of the potting mold coating based on the potting material

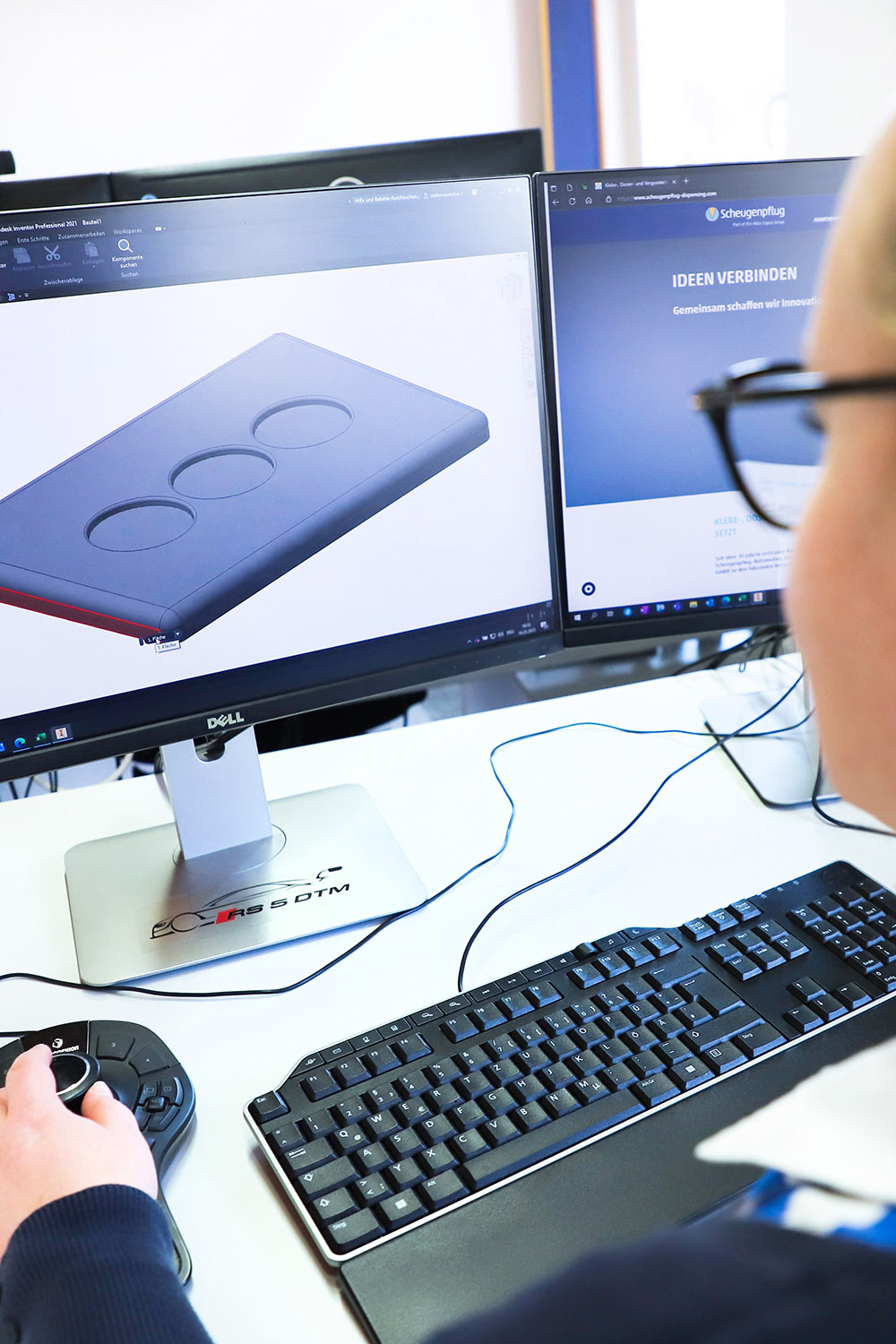

Design

Drawing of an accurate potting mold

Manufacture

Production of a negative mold, milling and coating of the potting mold

Production

Inserting the component, potting process, curing process, demolding Inserting the component, potting process, curing process, demolding